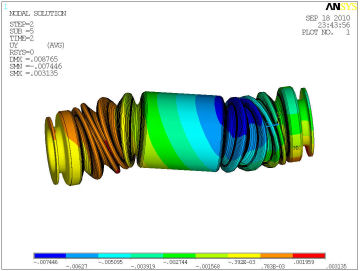

Composite Shafts and Couplings

Overview of Flexshaft Technology

Lawrie Technology, Inc. (LTI) flexible couplings are the result of 15 years development, exploring every prior approach to power transmission shafting with incorporated motion accommodation. Across all industries the transmission of shaft power must marry torque dense material solutions with geometrical details capable of sustaining imposed axial, lateral and bending displacements. Without such motion accommodation shafts would fail very quickly in fatigue. These displacements arise from thermal growth, airframe compliance, imperfect installations, etc. Typical high power applications include gas turbine drives for aircraft propellers and rotors, pumps, blowers, compressors, generators and cooling towers.

The LTI solution presents the only successful new technology in 50 years. Our shafts integrate the flexible elements at each end with the spacing tube used to transmit power without the need for separate split lines to connect these regions. The result is a torque dense, all-composite, shaft with infinite fatigue life, improved motion accommodation, and weight saving in excess of 80% in most cases.

The LTI family of flexible power transmission shafts includes industrial shafting and aerospace derivatives (typically helicopter shafts). Succinctly, the industrial cooling towers family approximately doubles the torque density (800 series peak torque increases 66,000 in.lb to 130,000 in.lbf, for example) compared with the highly cost-effective tower series. Aerospace shafting is custom designed for each application and typically marries the high torque density of an industrial shaft with infinite life motion accomodation as much as four times larger for special situations.