Supporting Equipment List

Software

- ANSYS multi-physics finite element program

- Solid Works 3D design

- Edge CAM mill and lathe package

- (All software is the most up-to-date version available,

with current maintenance contracts in place)

Test Equipment

- Universal test machines from 10 grams full scale to 60,000 lbs

- Torque test facility to 1 million in·lb x 6in length

- Torque test facility to 200,000 in·lb x 8ft length

- Variable speed spin test with angular misalignment to 10°

- Scales from gram balance up to 5,000 lb

- Complete microscopy lab with data analysis software

- Standard composite equipment; gel timers, viscometers, etc.

Composite Manufacturing

- Pultrusion equipment with up to 20,000 lb pull force

- Filament winding up to 8ft diameter x 15ft length

- 60in width Rosenthal slitter

- 4ft x 10ft vacuum lay-up table and supporting equipment

- 38in x 38in x 5in 100 psi press-clave

- 2 – 20 ton heated hydraulic presses

- 10in x 12in x 30in sintering furnace to 2300°F

- Several ovens, up to 911 cubic feet, with accurate temperature control

- Centrifuging equipment

- Multiple Meter/Mix machines, small and large scale

Tool Room

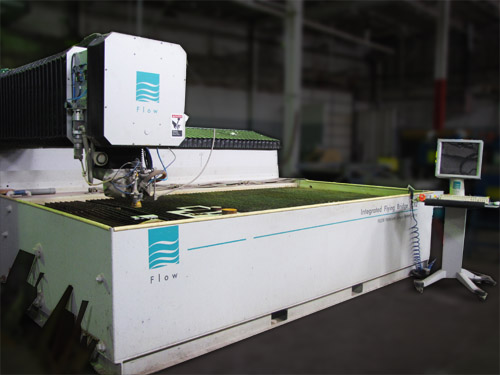

- 6ft x 12ft FLOW water-jet with dynamic cutting head

- Hitachi_Seiki 20in x 40in Vertical Machining Center

- Ultima vertical mill with Proto-Trak control

- Okuma LC-40 Turning Center

- 26in x 234in American Pacemaker Lathe with CNC control

- 14in x 80in 600 Lathe with CNC control

- 14in x 54in American Pacemaker manual lathe

- Sharp vertical manual mill

- 6in x 12in Brown and Sharpe surface grinder

- 6in x 18in Boyar-Shultz surface grinder

- 5in x 10in sinker EDM

- HE&M horizontal band saw to 14” diameter