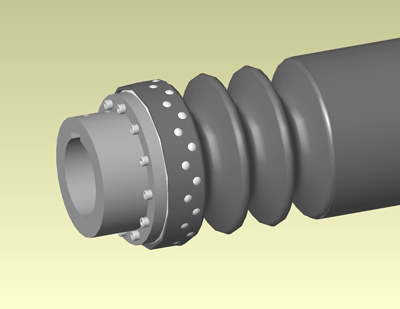

Cooling Tower Driveshafts

Highlights

- Outstanding performance evolved from a helicopter heritage

- Designed specifically for cooling tower duty

- 100% fully integral carbon fiber epoxy construction. No flex element corrosion concerns

- Stainless flanged interface standard

- One piece construction. No need to re-balance - ever!

- Lengths up to 14' (4.3m)

- Lightest solution in the world! No more struggling with cranes. LTI shafts are typically 75% lighter than all competing technology (including those with carbon fiber spacing tubes)

- Highly engineered solutions incorporate industry leading torque density, motion accommodation and zero-growth spacing tubes. As part of a paradigm shift in flexible drive trains LTI has incorporated a Coefficient of Thermal Expansion (CTE) close to zero such that even 14 ft long drive shafts do not unacceptably load flex elements under thermal load

- LTI flex shafts are maintenance free and constant velocity1

Features

The driveshaft transmits power from the output shaft of the motor to the input shaft of the gear reducer. Because the driveshaft operates within the tower, it must be highly corrosion resistant, lightweight for easy installation and well balanced for high speed operation. Transmitting full motor power - including stall torque - over significant distances it must also accommodate parallel offset of the end faces due to structural movement of the tower (including thermal growth) and imperfect installation. This parallel offset or lateral deformation results in an equal and opposite bending moment / rotation in the flex elements at each end with consequential high cycle fatigue considerations.

» DOWNLOAD MORE INFORMATION - LTI COOLING TOWER DRIVE SHAFTS